When a system is down, you need options. We maintain a small pool of new stock, a broader catalogue of refurbished spares, and direct routes to new kit via OEM and distributor partners.

Every item is tested, graded, and tracked by serial, with warranty and chain-of-custody from shelf to site. Choose cheaper refurbished for speed and value, or partner-sourced new when you need exact spec and current lifecycle.

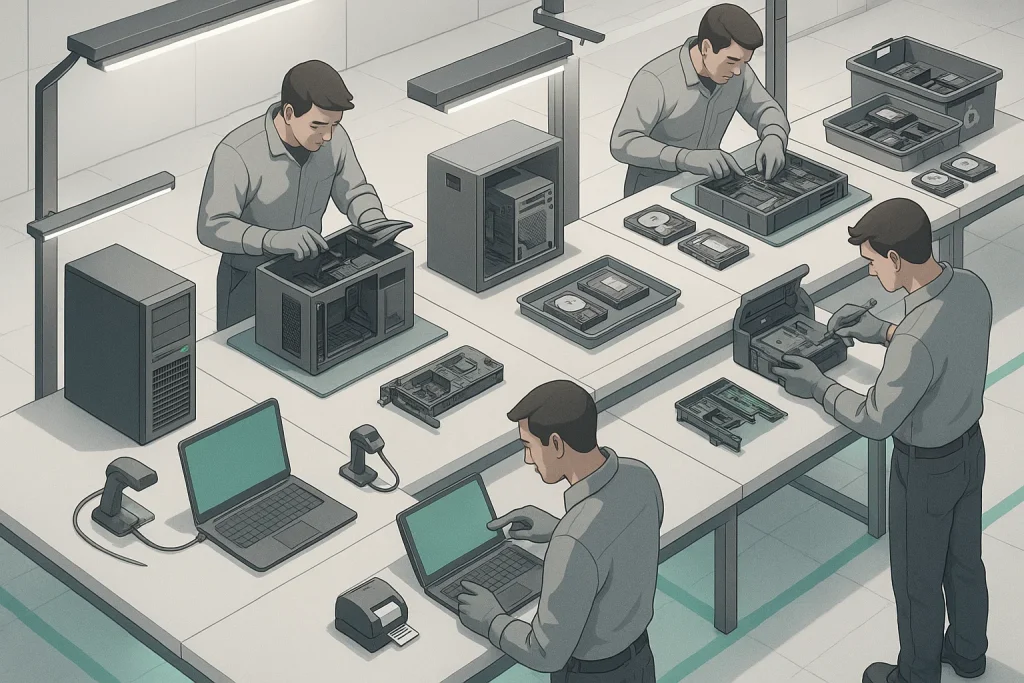

Every procurement request begins with matching the right component to the right requirement. You share the device model, FRU or technical specification, and we confirm new versus refurbished options with realistic lead times. Our small stock of new items and deep catalogue of tested spares mean we can respond within hours — not weeks — to restore uptime.

Packing is tailored to the part. Components are secured in anti-static wrap, foam inserts, or flight cases depending on weight and fragility. Each shipment is sealed and transported via GPS-tracked courier under chain-of-custody control, ensuring a verifiable handover on delivery.

Finally, a detailed report is issued for your records. Dispatch notes, serials, warranty data, and evidence photos are filed against the job reference. For clients with managed spares pools, we reconcile held stock monthly to maintain accurate inventory and readiness for the next deployment.

Need IT equipment?

Behind the tools is method: security-cleared teams, RAMS and permits, ESD discipline, lift/weight limits, and a documented chain-of-custody. We pre-plan routes, label matrices, and load restraint (bars and ratchet straps) so cases travel on unbranded GPS-tracked air-ride vehicles with no hub transfers. The result is a clean, auditable migration—safe lifts, tidy patching, verified links, and an evidence pack that stands up to any internal or external review.

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies.