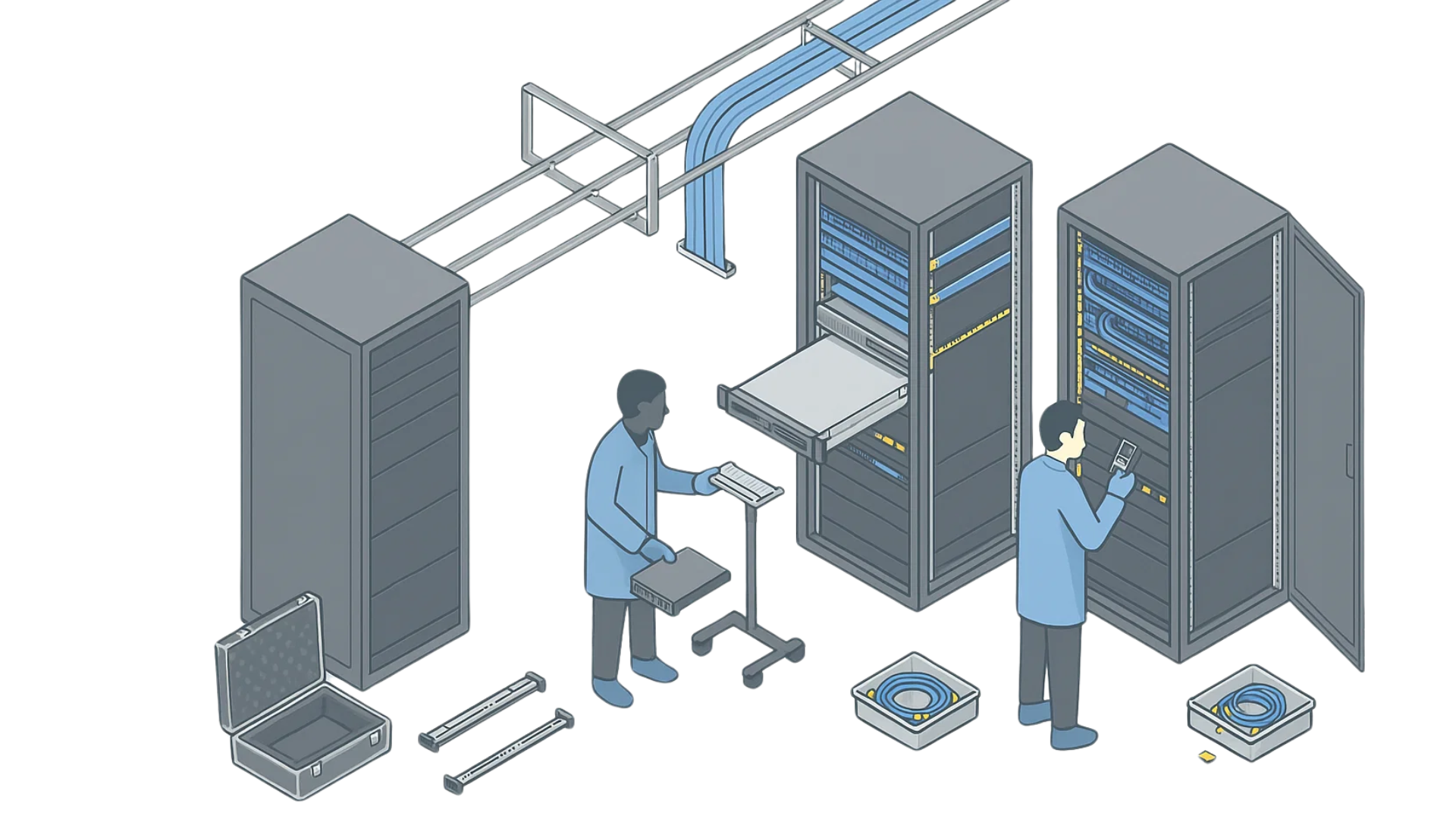

Our projects are delivered by trained and optionally DBS or security-cleared engineers working to a documented method: RAMS, toolbox talks, permits to work, and a change-controlled runbook. Every task—de-rack, move, re-rack, and re-cable—is owned by a single PM and executed by dual teams for speed, separation of duties, and safety.

We keep standards visible. Engineers wear anti-static PPE and follow ESD handling, cable discipline, and lift/weight compliance. Evidence—photos, test results, and sign-offs—is captured as we go, so handover is fast, traceable, and audit-ready.

From pre-start brief to final sign-off, your migration is observable, auditable, and accountable. We evidence the work as we perform it—tests, photos, and checklists—so there are no surprises at cutover and no gaps at handover.

The result: clean installs, predictable timelines, and a paper trail that stands up to any internal or external audit.

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies.