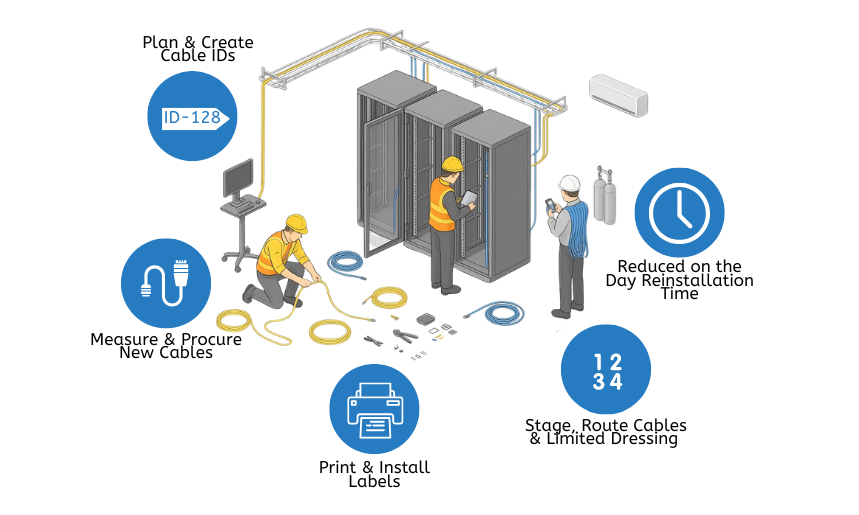

We install the cabling before cutover: build port maps, a simple TIA-606–style ID scheme, and a label matrix, then supply Cat6/6A and fibre (OM4/OS2, MPO/MTP) either as bulk reels used until complete or exact, measured looms per rack/RU/route.

Labels can be produced on- or off-site and installed on- or off-site (wrap-flag, self-lam, heat-shrink, and QR/barcode options). Both ends—plus optional mid-span markers—are colour-coded by service and tied to the live patch schedule for a clean audit trail.

Physical cable trace and pathway survey: tray/trunking layout, fill-rate %, drop points, brush-strip locations, copper/fibre separation, EMI risk and minimum bend-radius by type.

Confirm cable class (Cat6/6A LSZH/CPR), PoE class requirements, fibre media (OM4/OS2), connector strategy (LC duplex, MPO-12/24), patch-panel density, and power baseline (A/B PDUs, C13/C14 & C19/C20 needs). Outputs: accurate lengths (±2–5%), counts, and routing constraints.

We put a TIA-606–style governance layer around pre-cabling so every endpoint stays traceable from plan to handover. That means an agreed ID convention, a colour-banded label matrix with optional QR/barcodes that resolve to port metadata, and the right media specs (print method, adhesive, LSZH/temperature) signed off in advance. Together, these drive clean port maps and patch schedules, including polarity and A/B power mapping, so change control and audit are straightforward rather than reactive.

From planning into staging, each loom is pre-kitted by destination RU, photo-QA’d, and sealed for handoff, then delivered dressed with Velcro (no zip-ties), correct bend radius, and clear copper/fibre segregation. We also include spares and an on-site label print kit, so any last-minute variance can be absorbed without extending the cutover window—maintaining speed while preserving a clean, verifiable trail.

Want to find out more?

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies.