We specialise in moving live, fully populated cabinets safely and efficiently. Before any rack is moved, we complete a route and clearance survey, confirm lift capacities and floor loadings, plan turns and gradients, and produce a concise move runbook with risks, mitigations, and approvals.

Racks MUST be “rated” for populated moves so please ensure you check in advance as your dedicated project manager will need to know!

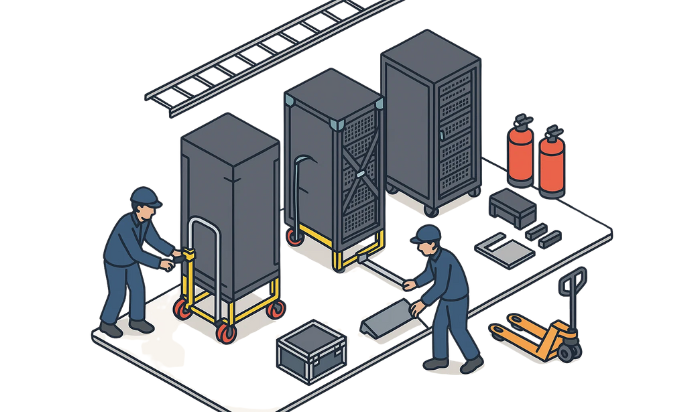

On the day, each rack is braced and protected (front X-straps, foam door blocks, corner guards, internal brace shelves and rack covers), fitted to paired rack-moving dollies or castor skates. Assets travel under tamper-sealed chain-of-custody with GPS tracking. At destination we re-site, level, and validate airflow, power, and service status before handover.

Want to find out more?

Our engineers bring the full move kit—paired rack dollies, skates, ramps, track-mats, pads, straps, corner guards, covers, and calibrated shock/tilt indicators—plus a clear runbook with route controls, roles, and comms.

Every move is insured and logged with tamper seals, manifests, and GPS tracking. At destination we re-site, level, and validate, then provide a photo record and acceptance report so the rack is back in service with confidence.

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies.