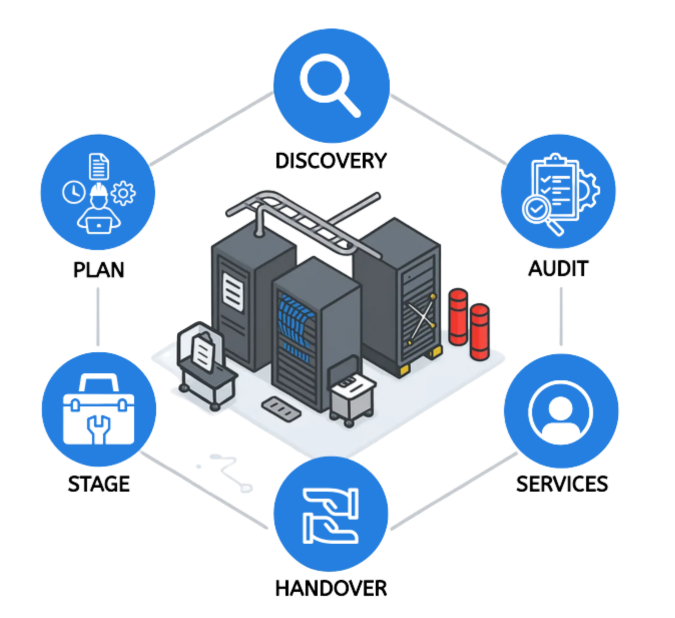

We coordinate end-to-end: audits, ID schemes, pre-cable/pre-label staging, populated rack logistics, chain-of-custody, re-site validation, and documentation. Your PM owns the plan, scope, risk, resources, comms, approvals, and evidence—from the first discovery call to the signed handover.

We wrap every migration in a TIA-606 governance layer owned by one PM, then plan not just the move but the change: rack consolidation/rightsizing, platform swaps, and tech refresh. The team locks the ID scheme, label matrix, port maps and a design freeze, raises procurement for new kit (racks, PDUs, optics, transceivers) and cable procurement (Cat6/6A & OM4/OS2—bulk reels vs exact lengths, spares policy, lead-time tracking).

We lock the runbook, route/lift plan, RAMS/permits and escalation lanes before the window, then drive a steady rhythm—weeklies in staging, dailies pre-cutover, hour-by-hour during change. CAB gates and a live RAID keep decisions fast, traceable and aligned across facilities, security, carriers and smart-hands.

Readiness gates confirm kit, pre-cabling, route protection and rollback; we timestamp each step and deliver tests, photos and brief hyper care.

Confirm sites, windows, business constraints, security, and success criteria; gather inventories and live-risk context.

Publish gantt, RACI, RAID, and communication plan; lock ID scheme, port maps, label matrix, and acceptance tests.

Track procurement and pre-cabling (bulk vs exact lengths), QA photos, bag-by-RU kitting, and rollback materials; readiness checklist to “go".

Runbook-driven tasks with timeboxed steps; populated racks braced, covered, dollied/skated, shock/tilt logged; GPS-tracked custody.

Position and level; reconnect A/B power; dress & segregate; Fluke DSX (copper), LSPM/OTDR (fibre), airflow checks, screenshots/photos.

Issue as-built, test packs (PDF), photo record, exceptions list, and actions; final sign-off and lessons learned. Handover of Infrastructure Planner.

A live RAID and CAB-ready change packs (runbook, rollback, go/no-go) sit beside route & lift plans, permits, security/insurance, and dedicated vehicles, so decisions are evidence-based, not improvised.

Staging covers pre-cabling and kitting by RU, but also decommission/commission flows: serial capture, asset tags, BIOS/firmware baselines, and ITAD for retired gear (certified data wipe/shred, WEEE-compliant recycling, resale where viable). Populated racks are braced, covered, dollied/skated, with shock/tilt logging and GPS custody; new hardware lands from procurement with DOA checks.

On arrival we re-site, level and validate: Fluke DSX (copper), LSPM/OTDR (fibre/MPO), A/B power load/continuity, airflow photos and connectivity tests. Handover includes as-builts, test packs, photo record, exceptions list, and updated inventories—so operations inherit a footprint that’s consolidated, refreshed, and provably ready.

Want to find out more?

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies.